That Rough Morning Feeling — And It’s Not Just You

Picture this: you hop into your Ram 1500 on a Tuesday morning, twist the key, and the engine stumbles. There’s a faint shudder at idle, and when you pull onto the highway, the acceleration just doesn’t have that familiar punch. You check the gas gauge — full. You check your foot — it’s definitely on the pedal. So what gives?

Nine times out of ten, a misfiring or worn spark plug is the culprit. And if your truck’s diagnostic code is pointing to a misfire on cylinder 2 specifically, you’ve landed in exactly the right place. Learning how to change spark plugs in a Ram 1500 cylinder 2 is one of the most satisfying and cost-effective pieces of DIY maintenance you can do. No dealership visit required. Just a Saturday morning, a few tools, and this guide.

Why Timely Spark Plug Changes Actually Matter

A lot of Ram 1500 owners treat spark plug replacement as one of those “I’ll get to it eventually” items on the maintenance list. But here’s the thing — spark plugs are literally what ignites the air-fuel mixture inside each cylinder. When cylinder 2 starts misfiring because of a worn plug, the ripple effect touches everything. Your fuel economy drops because unburned fuel is getting pushed out the exhaust instead of powering the engine. Your engine management system starts compensating, which can throw off timing and increase wear on other components. And over time, a persistent misfire can damage your catalytic converter — a repair that costs far more than a set of spark plugs.

For Ram 1500 maintenance in general, most mechanics recommend inspecting spark plugs around every 30,000 miles, though modern iridium or platinum plugs can last up to 100,000 miles under ideal conditions. The catch is that “ideal conditions” rarely describe a working truck that’s towing, hauling, or sitting in stop-and-go traffic. Staying on top of cylinder 2 spark plug replacement — and the other seven while you’re at it — keeps your 5.7L HEMI or 3.6L Pentastar running the way it was designed to.

Gather Your Tools Before You Pop the Hood

There’s nothing worse than getting elbow-deep into an engine bay and realizing you’re missing something. For this job, you’ll want a 3/8-inch drive ratchet and a short extension, a 5/8-inch spark plug socket (which has a rubber insert to hold the plug), a torque wrench to avoid over-tightening, a spark plug gap gauge or feeler gauge to confirm the new plug’s gap matches your engine’s specification, a set of needle-nose pliers or a pick tool to help disconnect the ignition coil connector, dielectric grease for the boot, and a pair of mechanic’s gloves to protect your hands from heat and sharp edges. If your Ram has been running recently, give the engine at least 30 minutes to cool down — working on a hot engine is both dangerous and makes the plug harder to remove cleanly.

How to Change Spark Plugs in Ram 1500 Cylinder 2: The Full Procedure

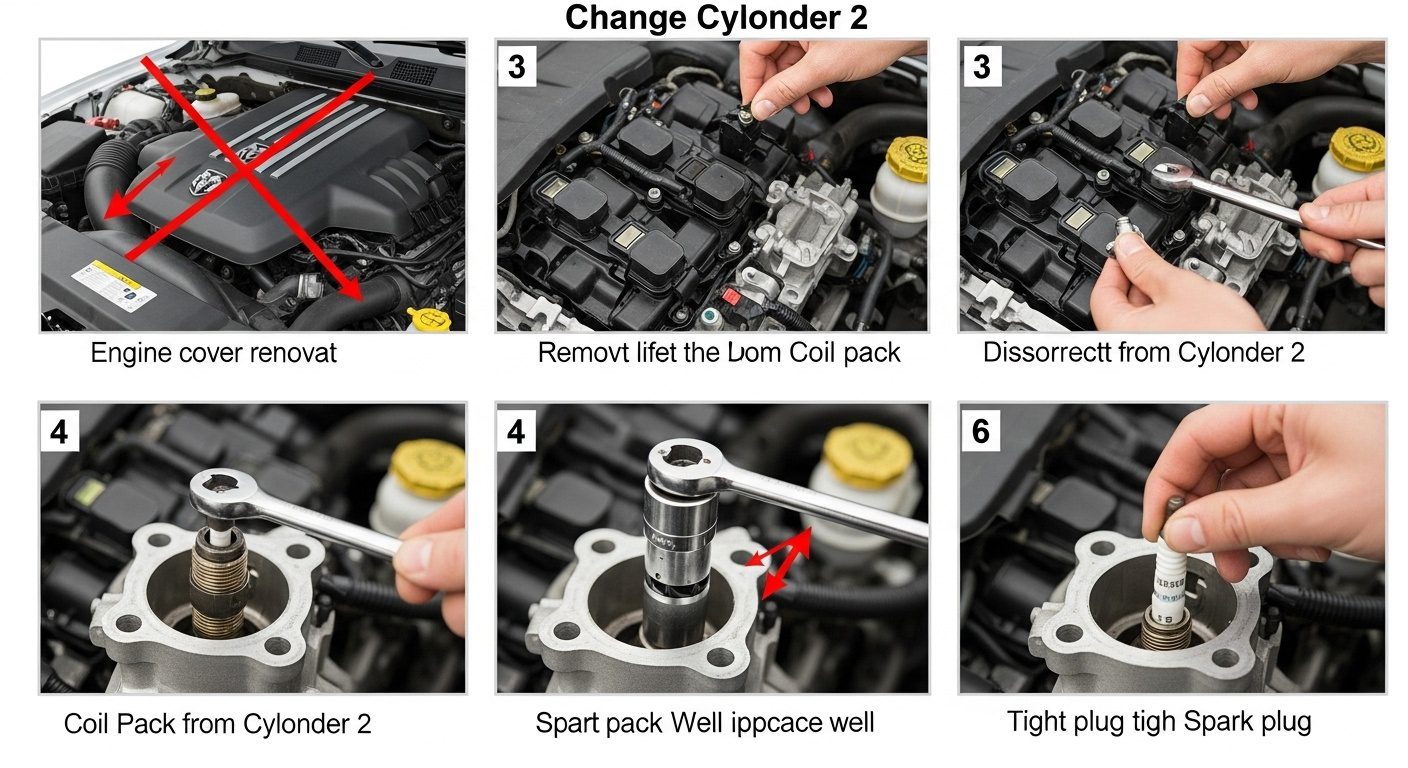

Starting with safety is non-negotiable. Park your truck on a flat, stable surface, engage the parking brake, and disconnect the negative terminal on your battery. This eliminates any risk of the engine accidentally cranking while your hands are near moving or electrical components. With the hood propped open, take a moment to locate cylinder 2. On the Ram 1500’s 5.7L HEMI, cylinders are numbered with odd numbers on the driver’s side (1, 3, 5, 7) and even numbers on the passenger side (2, 4, 6, 8). Cylinder 2 is the front-most cylinder on the passenger side of the engine. On the 3.6L V6, cylinder 2 is the middle cylinder on the front bank. If you’re unsure, consult your owner’s manual or a quick Google search with your specific engine.

Once you’ve located cylinder 2, find the ignition coil-on-plug sitting directly on top of it. Press the release tab on the electrical connector and gently wiggle it free. Use your needle-nose pliers if the connector is stubborn — but be gentle, because cracking a connector out here means more headaches. Next, remove the single bolt holding the coil in place using your ratchet, then pull the coil straight up and out. Set it aside somewhere clean.

Now you’re looking at the top of the spark plug. Attach your spark plug socket to the extension and ratchet, lower it carefully into the plug well until it seats over the plug, and turn counterclockwise to break it loose. If it’s really stuck — which can happen after years of heat cycling — apply a small amount of penetrating oil and let it sit for ten minutes before trying again. Once loose, remove it slowly and keep it upright so no debris falls into the cylinder.

Before installing the new plug, take your gap gauge and check that the electrode gap matches your engine’s specification. For most Ram 1500 engines, the spec falls around 0.040 to 0.044 inches, but always verify against your owner’s manual or the plug manufacturer’s instructions. If the gap needs adjusting, carefully bend the ground electrode — never the center electrode — until it’s correct.

Thread the new spark plug in by hand first. This is important. Hand-threading prevents cross-threading, which is one of the most painful (and expensive) mistakes you can make during this job. Once the plug is hand-tight, use your torque wrench to snug it down to the manufacturer’s specification — typically around 13 to 20 ft-lbs depending on your engine. Do not overtighten. Apply a thin film of dielectric grease to the inside of the ignition coil boot, then reinstall the coil, tighten its retaining bolt, and reconnect the electrical connector until you hear it click into place.

Reconnect your battery’s negative terminal, start the truck, and let it idle for a minute or two. Take it for a short drive to confirm the rough idle and hesitation are gone. If you had a stored misfire code, use an OBD-II scanner to clear it — or simply drive the truck through a few key cycles and it will often clear on its own once the computer sees the misfire is resolved.

Common Pitfalls to Watch Out For

The biggest mistake DIYers make during cylinder 2 spark plug replacement — and any spark plug job, really — is cross-threading. If you feel any resistance when hand-threading the new plug, stop immediately, back it out, and start over. A cross-threaded plug can strip the threads in the cylinder head, and repairing that is a job that belongs in a shop.

Incorrect gap is another common issue. Some new plugs come pre-gapped, but “pre-gapped” doesn’t always mean gapped for your specific engine. Always verify. Over-tightening is equally problematic — it can crack the ceramic insulator or deform the shell, both of which lead to a misfire right out of the gate. Finally, if the engine was hot when you started, you risk seizing the plug as you try to remove it. Cool engine, every time.

When It’s Time to Call a Professional

Most Ram 1500 owners can handle this job confidently with the steps above. But there are situations where you should put the tools down and make a call. If you replace the spark plug and the cylinder 2 misfire code immediately comes back, the problem might be deeper — a faulty ignition coil, a fuel injector issue, or even a compression problem. A compression test can help diagnose this, but if your readings on cylinder 2 are significantly lower than the others, that points to internal engine wear that only a qualified mechanic should address. Persistent rough idling after a fresh plug change, a strong smell of raw fuel from the exhaust, or visible damage to the ignition coil are all signs that something beyond a simple cylinder 2 spark plug replacement is going on.

There’s no shame in recognizing when a job has outgrown the driveway. Getting a professional diagnosis early saves you from chasing symptoms for weeks and spending money on parts that aren’t the root cause.

You’ve Got This — Now Go Make That HEMI Happy

Knowing how to change spark plugs in a Ram 1500 cylinder 2 is a genuinely empowering skill, and it’s one that pays dividends every time you hit the accelerator and feel that smooth, confident pull. Fresh plugs restore proper combustion, improve throttle response, bring back fuel efficiency, and protect the rest of your engine from the stress of an ongoing misfire. As part of your overall Ram 1500 maintenance routine, it’s one of the highest-return tasks you can do with your own two hands.

If this guide helped you tackle the job, leave a comment below and let us know how it went. Did you run into any surprises — a stuck plug, a tricky coil connector, or anything else? Share your experience so other Ram owners can learn from it. And if you have questions before you dive in, drop them in the comments and we’ll do our best to help you out.

Now go grab that ratchet — your truck is waiting.

0 Comments