It may seem that how to rewire a 2012 Ram 1500 trailer lights is one of those projects that you will not want to do on a Saturday, but in fact it is one of those projects that you will save hundreds of dollars at the mechanic. It does not matter whether you will be working on corroded connections, damaged wiring or simply you are interested in updating your lighting system in the trailer, this guide will take you through every single step.

Your Ram 1500 would also be worthy of a good trailer light connection, particularly when you are transporting equipment, boats or campers throughout town or even the nation. Now we will get down to how to make those trailer lights work in the way they are supposed to.

Why you should have your Ram 1500 Trailer Lights rewired in 2012.

Trailer light problems do not come into existence randomly. Your road salt-moisture and general wear and tear cause your factory wiring harness to begin showing age after years of exposure.

There are flickering lights, one hand side working and the other side not working or total loss of electrical power. The issue is not even the truck sometimes, but it is the trailer connector to which the truck is attached.

Trailer Light Problems that are common with Ram 1500 Trucks.

The 7 pin and the 4 pin connector of these trucks is infamous in a few particular problems:

Corroded deposits in the connector pins.

Damage or intermittent fail since Ground Wires are broken.

Melted circuit connectors used in overloaded circuits.

Torn insulation that revealed bare wire.

Rupture of factory connector on frame mounting point.

The towing package wiring of your truck is the rear light assembly with the frame to the hitch part of the frame. The failure of any component of this circuit will result in possible safety problems and certainly a share of agitated glances by other road users.

Resource Material and Equipment.

You can get all the wiring of your Ram in one place before you begin tearing it apart. There is no worse thing than being midway into a project and you notice that you need to run some parts.

Essential Tools for the Job

Wire cutters and wire stripper.

Hot shrink tubes and electrical tape.

Installation tool to make secure connections.

Circuit tester Multimeter.

Socket set (10mm most commonly used 13mm)

Flashlight or work light

Zip Commands to hold on to new wiring.

Required Wiring Components

7-pin or 4 pin trailer connector (whichever you have now)

Multicolored skin- peoples of 16-gauge proper at least, coding.

Butt connector and ring terminals.

Weather stripping dielectric grease.

Thread loom Protecting exposed sections.

T-tap connector(s) (not compulsory but useful)

There are trailer wiring kits of specific 2012 Ram 1500 truck parts available in most auto parts stores. These kits have color-coded wires which are to match factory requirements and thus the task is made much easier.

Trailer Wiring the Ram 1500.

The 2012 Ram 1500 has a multiplexed electrical system, which simply refers to the fact that the computer dictates when and how the trailer lights are to operate. This is significant since you cannot simply tap an old wire and get things going.

Depending on the towing package you ordered, your truck probably either had a 4-way flat connector or a 7-way round connector. The 7-way is more functional with electric brakes and auxiliary power.

Standard Wire Color Codes

This is what the wires of a typical trailer wiring configuration do:

White wire, Ground connection = (necessary to all)

Brown wire = A tail light and running lights.

Yellow wire = brake light and left turn signal.

Green wire= brake light and right turn signal.

Blue wire = Electric brake controller (7-pin only)

Red wire = Auxiliary (7-pin only) 12V power.

Purple/Black wire = Reverse lights (only 7 pin)

Constantly check your truck with a wiring diagram to determine the correct wiring you are cutting before doing it. Ram would switch between trim levels and production dates occasionally.

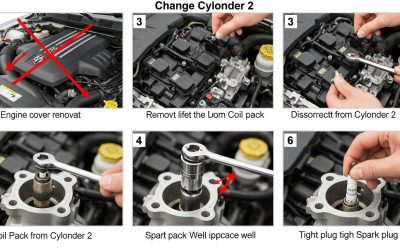

Wireless Guide: Rewiring a 2012 Ram 1500 Trailer Lights.

This is where we are getting down to business. This is a process that can be done in 1-2 hours provided that you go through all the connections methodically and do not hurry.

Find a flat piece of terrain and park your truck there, and first disconnect the negative battery cable. This also avoids cases of accident shorts when handling uncovered wires.

Step 1 Find the Old Connector and Remove it.

This is compatible with Ram factory trailer connector on your 2012, which fits at the side of the bumper commonly at the back on the driver side of the hitch receiver. It comes mounted with a mounting bracket attached with one or two bolts.

Take out the bolts and tug the connector. Follow the wiring towards the front of the truck–it is apt to run about the frame rail on the driver side.

2. Check the Factory Wiring Harness.

Before commencing the process of cutting wires, check the whole factory harness. In some cases, it may be that it is only the connector that is bad and you save yourself the trouble by simply replacing it.

Agreement In the areas of checking insulation, naked copper, or where wires have rubbed through the frame. In case the harness appears nice until the back-light assembly, then connector replacement may be all that is needed.

Step 3:Access the Rear Light Assembly Connections

Open your tailgate and take out the tail light assemblies of both sides. The back of the lights will be covered with plastic panels, which you will have to take out of the inside of the bed–it’s usually only a few push clips and perhaps a couple of screws.

The wiring of the factory is inserted into the rear of every assembly of lights. These are your points of tapping trailer circuit.

And the fourth step is to label and test every wire circuit.

Make sure that you use your multimeter in order to determine the wires that manage what functions. Switch on your parking lights, press your brakes, and switch every turn signal and check the light assembly voltage.

Note the color of wire that represents each of the functions. This avoids confusion in future as you are connecting in cozy areas beneath the truck.

Step 4: Re-fits New Wiring to the Hitch Areas.

When rewiring entire, make new wires between the tail light assemblies and out to where you are going to have your connector. Installation will be best done along the factory routing along the frame rail.

A wire loom or split tubing will be used to insulate the wiring against road trash and sharp components. Use zip ties at a mark of 12-18 inch to ensure that it does not sag or rub.

Step 5: Find the right connections of wires.

Here the issue of quality counts. Never simply bend wires together and secure them with tape, it is beckoning trouble in the future.

Crimp connectors with a heat shrink covering should be used on all connections. Once crimped, heat the connection to ensure the connection is sealed out to moisture. Apply a little dielectric grease in each connector.

Step 6: Equipment installed : Install the New Trailer connector.

Install your new connector 7-pin or 4-pin with the factory mounting place. Ensure that it is in its proper position such that trailers can be easily connected without straining the connection.

Connect the wires based on your previous testing as well as on your standard color code system. Before proceeding, be sure to check each and every connection.

Step 7: Ground Wire Modeled Properly.

The connection of the ground is likely to be the most significant aspect of the entire system. Most of the trailer light problems are brought about by a bad ground.

Locate a place of clean and bare metal on the frame to fix your ground wire with the help of a ring terminal and self-tapping screw. Cleanse the paint or rust off to make sure that there is solid contact between the metal and metal.

Step 8: Check That All Works Before Butting Up.

After reconnecting your battery, check all the stuff prior to adjoining panels again. Insert a connector into a trailer or a circuit tester which fits into your connector.

Test the following functions individually:

Running lights

Left turn signal

Right turn signal

Brake lights

Reverse lights (if 7-pin)

Auxiliary power (if 7-pin)

Now fix what is going wrong when all is available. Believe me, you will not want to put it all together again and discover that one of the circuits is not functioning.

Common Problems after Rewiring Troubleshooting.

Despite the attention to work, not everything starts on the first attempt. The most common problems can be diagnosed in the following way.

One Half Labor, Not the Other.

This practically only indicates bad earth connection or reversed wire at one end. Ensure that your ground wire has connected solidly and make sure you did not switch the yellow wire and the green one by mistake.

Measure the voltage on the connector pins and when a person was using the lights somebody measures the current on your multimeter. You need to have 12V when all functions are switched on.

All Lights Work But Are Dim

Dark lights are usually an indication that there is a high resistance connection somewhere in the circuit. This may be rotten crimps or an incorrect wire gauge as well as a bad ground.

Test all of your crimp connections as well as fix any of the loose connections. Ensure that you did not use less than 16-gauge wire because less resistance will cause a problem with lights on the trailer.

Work on Truck lights off Trailer lights off.

When you have the lights on your truck operating and the ones on the trailer out but are not working, then the fault is either in the connector itself or it is in the wiring of the trailer. Wipe connector pins with electrical contact cleaner, and test with some other trailer, where possible.

The connector pins occasionally become protruded in the connector housing and fail to connect when inserted. It is important to pull the connector pin forward until it fits in its place.

A brake controller problem affects (7-Pin Systems)

Electric brake controller circuit is more sensitive compared to lighting circuits. When your brakes are malfunctions, lights work, and you are fine, also test that the blue wire is correctly charged as well, and also, that your controller possesses the correct programs.

Your Ram of 2012 could have a controller that is built into the car, or it could be an aftermarket device. Ensuring that the settings of the controller are correct corresponding to the specifications of the brakings that the trailer has.

Trailer Wiring System: How to upgrade yours.

As long as you have everything out of the way, think of a few upgrades that will be a blessing in towing life in the future.

Adding a 7-Pin Connector

When you have a 4-pin connector in your truck at the moment and are intending to tow bigger trailers then it would be reasonable to upgrade to a 7-pin connector. Circuits will be required to add electric brakes, auxiliary power and reverse lights.

This involves some extra wiring back into your brake controller (unless it is factory fitted) and some tapping into your reverse light circuit. It is more laborious but it is also very helpful.

Fitting Wiring Harness with Circuit Protection in built into it.

Aftermarket T- connector harness should directly fit into wiring that is already in place without the need of cutting a wire. The ones also have built-in fuses and circuit breakers to guard the electrical system of your truck.

These are ideal when you desire a cleaner installation as well as when you do not mind paying a little more. There are harnesses that come in brands such as Curt, Reese, and Hopkins in Ram-specific brands.

Installation of an Auxiliary Reverse Light Circuit.

Trailers are also being outfitted with reverse lights activated by the tow vehicle. When backing up in the dark you may add this circuit to light up behind your trailer in case you are running a 7 pin connection.

Connect either reverse light at the back of your truck and make a special wire to the purple or black pin (depending on your connector configuration).

How to keep Your New Trailer Light Wiring.

A good rewire will last 5-10 years with little upkeep, although maintaining the system will even increase its lifespan.

Always wipe your connector pins with electrical cleaner. Add new dielectric grease at least once every year or prior to significant towing excursions.

Seasonal Maintenance Tips

Check all connections before winter, to see whether they are corroded. Electrical connections are deteriorated more quickly by road salt than by practically anything.

Take off with a connector cover not in active towing. These rubber covers prevent the pins against moisture and debris.

Before Every Towing Trip What to Check.

It is important to check your trailer lights prior to getting in the car:

Install the trailer and test everything.

Check connector pins on whether they are damaged or corroded.

ensure that the ground connection remains solid.

Find any loose or rubbing wires.

Ensure that the connector is well-mounted.

Five minutes of inspection will get you out of a roadside breakdown or a ticket issued by a highway patrol officer who notices that your lights are not functioning.

Price Comparison: Home and DIY vs Nomadicbtw.

This saves you a lot of money doing this job yourself as opposed to shop rates. It is as follows in terms of cost.

DIY Materials Cost

The full trailer wiring system of a 2012 Ram 1500 costs between 40 and 80 dollars with or without 4-pin and 7-pin options. Tools(tools, crimpers, wire strippers, and a multimeter): Add one more $20-30 too.

Total Do it yourself: $60-110 and 1-2 hours of your time.

Installation Cost of professionals.

Some shops usually install trailer wiring at the cost of between $150-300. Add in another 50-80 parts markup and you are at 200-380.

Self-doing helps to save between 140 and 270 dollars. And you have the added advantage of knowing how to trouble shoot and fix problems yourself.

Trailer Lights Rewiring Safety.

The automotive electrical systems work will only need elementary safety knowledge. Nothing about is especially objectionable provided you observe common-sense precautions.

Never work with with the battery connected. Your computer modules in your truck can get damaged due to short circuit or cause a fire.

How to keep Your Truck Electrical System safe.

The 2012 Ram 1500 has several control modules that interact via CANbus networks. The wrong wiring may confuse these systems and indicate the presence of check engine lights or other warning messages.

Do not open off any wires and even tap them randomly without knowing what they do. Before connecting a wiring diagram to a multimeter test to ensure that it is functional.

Fire Prevention Best Practice.

Install ampere wire of the correct size. The effects of the trailer lighting can be safely permitted using 16-gauge but not less.

Always have inline fuses on new circuits. Position fuses are those fuses that shield the total circuit length and serve as a protection of the power source.

Trailer Lights legal requirements.

All the states need efficient trailer lights during towing. Being pulled over due to non-operational lights may cost you money and even the impounding of your trailer until the problem is fixed.

In your trailer, you will need:

Brake lights can be seen over 500 feet.

Turn signals on both sides

Night visibility tail lights.

Light on the plate that is used to illuminate the plate.

Side marker lights and reflectors are also needed with bigger trailers. Check the needs of your state in case you are towing a trailer that is wider than 80 inches or longer than 15 feet.

Conclusion

The ability to adjust the 2012 Ram 1500 trailer lights system to rewire, would enable you to have one of the most vital aspects of towing a truck under your control. It can be built up with simple tools, good material and just several hours of concentrated effort and you can have a dependable electrical connection that will last you years.

The secret is to move step by step, ensure you do good relationships and do everything before deciding to call the job finished. The steps involved in the replacement of a corroded factory connector or in the entire upgrade of the harness are the same basic ones.

The Ram 1500 is a towing vehicle and with the correct trailer lights, you can exercise your towing capacity safely and within the law. Barnabas, now go and use those new wiring skills.

Frequently Asked Questions

Q: Can I have a 4 pin connector when my trailer is supposed to have a 7 pin connector?

A: You will be able to use an adapter but you will lose such functions as electric brakes and supplementary power. It is okay to use occasionally, however when it comes to frequent towing, then one should upgrade to a 7-pin system.

Question: Why do my trailer lights not light up all stuck?

A: Intermittent operation is almost always a case of a bad ground connection or corroded connector pin. Wipe down all the equipment then reestablish communication with the ground to eliminate this problem.

Question: Should I have brake controller with trailer lights on my 2012 Ram1500?

A: Not to cover the bare light functions, but you do need one that has the electric lighting brakes on your trailer. A connector of 7 pin is attached to the blue wire by the brake controller.

condition: Is it possible to be able to splice into the tail light wiring of my truck, without removing any part?

A: This can be done with T-tap connectors, but it is easier to do it with the tail light assemblies removed to provide better access and to end up with cleaner and more reliable connections that are easier to debug in the future.

Q: I have a truck and I would like to know your advice on whether or not the vehicle has a factory towing picture.

A: look under the hitch and around your hitch receiver there is a 7 pin connector and under the dash there should be a brake controller. You can also check with a Ram dealer using your VIN–the factory towing package also comes with an upgraded cooling and suspension parts as well.

Q: Is there any rewiring of my trailer lights that will affect my warranty of my truck?

A: In case your 2012 Ram is still under extended warranty, any electrical problems could be subject to nullification of warranty in case improper wiring modifications are made. Provide factory-like connections and use OEM to reduce the possibility of any concerns.

0 Comments